Household elevator have specific electrical and mechanical requirements to ensure their safe and efficient operation. These requirements can vary depending on the elevator type, model, and manufacturer, but here are some general considerations:

Electrical Requirements:

Power Supply: Household elevators typically require a dedicated electrical circuit with the appropriate voltage and amperage capacity. The voltage and amperage requirements will vary based on the elevator's size and type. Ensure that the electrical supply meets the manufacturer's specifications.

Emergency Power Backup: To ensure passenger safety, household elevators often include an emergency backup power system. This system is essential in case of power outages, and it typically includes a backup battery or generator to lower the elevator to the nearest floor and allow passengers to exit safely.

Control Panel: Elevators have a control panel that requires electrical power to operate. This control panel manages the elevator's movements, door operation, and safety features.

Lighting: Elevator cars and entrances on each floor should have proper lighting for safety and convenience. Lighting should meet local building code requirements.

Communication System: An emergency communication system is essential for passenger safety. This typically includes an intercom or telephone system that allows passengers to communicate with someone in case of an emergency.

Mechanical Requirements:

Elevator Drive System: The type of drive system in a household elevator can vary. Common types include hydraulic and traction (cable-driven) systems. The mechanical components associated with the drive system, such as the hydraulic pump or traction machine, must be properly sized and maintained.

Counterweights: Many elevators use counterweights to balance the load and reduce the energy required to operate the elevator. The counterweights must be correctly installed and maintained.

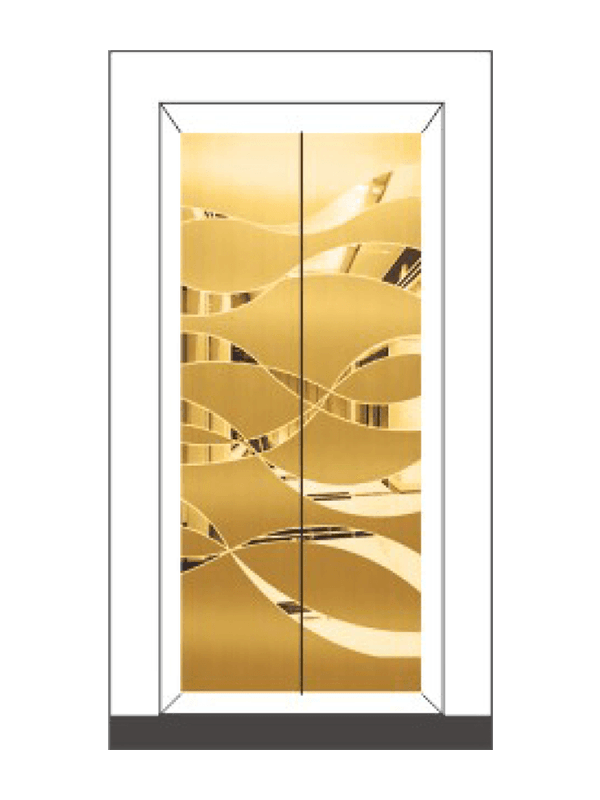

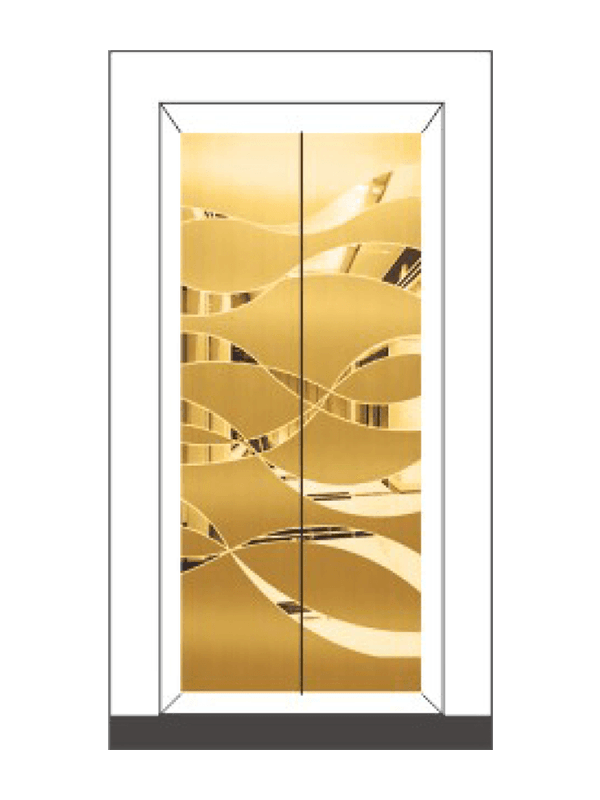

Doors and Door Operators: The mechanical components associated with the elevator doors are critical for passenger safety. This includes door operators, door panels, sensors, and safety features like door interlocks.

Safety Devices: Elevators are equipped with various safety devices, including emergency brakes, overspeed governors, and safety buffers. These mechanical components must be regularly inspected and maintained to ensure safe operation.

Carriage and Guide Rails: The elevator car and its associated guide rails must be properly aligned and maintained to prevent issues like misalignment or friction that can affect operation.

Safety Compliance: Elevators must meet safety standards and regulations, such as ASME A17.1 (the safety code for elevators and escalators in the United States). Compliance with these standards ensures the mechanical components are designed and installed for safe operation.

Regular Maintenance: Maintenance is essential for the mechanical components of an elevator. Regular inspections and servicing by qualified technicians help prevent breakdowns and ensure the elevator operates smoothly and safely.

English

English عربى

عربى Deutsch

Deutsch Español

Español Français

Français русский

русский 日本語

日本語 简体中文

简体中文